Cooling Systems to avoid Heat Stroke

Traditionally the philosophy of livestock work has been to minimize costs while maintaining acceptable results. This way of working had its meaning when the objective was to subsist and only had genetics of high rusticity, the “feed” was produced at home and the accommodation available was a sad cover. But the current situation is the economy of scale and the technical optimization of the process.

The birds we have today are those of yesterday what a Ferrari to a four cans. With this parallelism we want to emphasize that it is no longer worth taking care of them in any way. If we put cheap oil to the engine of a Ferrari, it is not that it is certain that it does not reach its maximum performance, but most likely we load the engine. So it is important to take care of all aspects of management, not because of the main reason to maximize production, but because of the risk of losing it completely because of the inability of animals to tolerate conditions for which they are no longer prepared.

As far as the environment is concerned, the birds present, according to age and strain, ideal conditions of temperature and humidity, two very interrelated variables. Within these ranges they feel comfortable and their metabolism destines the minimum necessary to the control of the corporal temperature, reason why they can destine the greater part of the food to produce. It is when we get out of these ranges that the problems begin.

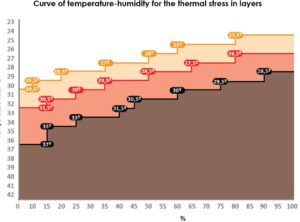

In the case of birds older than 4 weeks, it is recommended to keep below 40% humidity and 25 ° C. Birds can tolerate temperatures up to 35ºC, but in these situations it is advisable to keep the humidity low and a slight breeze to ensure that the perceived effective temperature is maintained within the Bearable by the animal. If we leave the range, as the temperature / humidity increases, there is a progressive depression of food consumption and increase of water consumption, associated with a drop in production. Arrived to extreme cases, given the physiological limitations of the birds to dissipate the heat, we can reach a situation of heat stroke with prostrations and deaths. This last situation is always undesirable, not only because of its gravity, but because it implies its tipped condition of the iceberg (how much will we have been losing in productivity due to poor housing?). Curve of temperature-humidity for the thermal stress in layers One of the differential facts of our latitudes is the rigor of summer, so we must be alert to its potential consequences. There are many strategies to minimize the effect of heat on poultry productivity, such as feed formulation and distribution, but the most immediate is through good environmental control with adequate ventilation and cooling systems. The first thing is to optimize the isolation of the ship and reduce the effect of the Sun with trees and painting the surfaces of white. After the limited effect that is achieved with fans, we must consider whether it would be convenient to install cooling or Evaporative cooling panels. The cooling panels are a system of cells on which a curtain of cold water is run to cool the air that enters the ship when passing through it, so that its operation is linked to that of ventilation. In contrast, Evaporative cooling base their effect on the heat dissipation that is achieved by evaporation of water droplets in the environment, so that they do not depend on ventilation but see their limited effectiveness in situations of high relative humidity. In any case, it is best to seek a professional who advises us on the Best option for our specific situation (local climatology and ship configuration). As far as the environment is concerned, the birds present, according to age and strain, ideal conditions of temperature and humidity. The panels are a system of cells on which a curtain of cold water is run to cool the air entering the ship as it passes through it.In terms of costs, both systems consume relatively little in terms of water and energy. In the case of the panels it is only a low pressure circuit, with little energy consumption, so the secret is to recycle the water (after cooling it in a tank). As for Misting, a compressor consumes a lot but the volumes to be Mist are so small that it is not a problem. In the installation, the Misting are somewhat more expensive for It is a pressure system. Panels are cheaper, but require more material, and if you do not take good care you need to renew them frequently. In both cases the most important thing is to minimize the cost of maintenance with a good management: keep the water of the circuits within sanitary quality standards (chlorination) and low lime content (to avoid obstructions). In the market the offer is wide and diverse, in prices and qualities. We must consider certain aspects: with the Misting system we must prioritize a suitable pressure and micro-quills that produce drops of water of a sufficiently small size. Otherwise we run the risk of wetting the bed and the animals, getting an effect contrary to the desired. With the panels you have to evaluate the quality of the material of the cells, its resistance to blows and inclement weather. If they are easily removable we can save them in winter when they are not used to extend their productive life. The Mist cooling system base their effect on the dissipation of heat that is obtained by evaporation of water droplets in the environment.